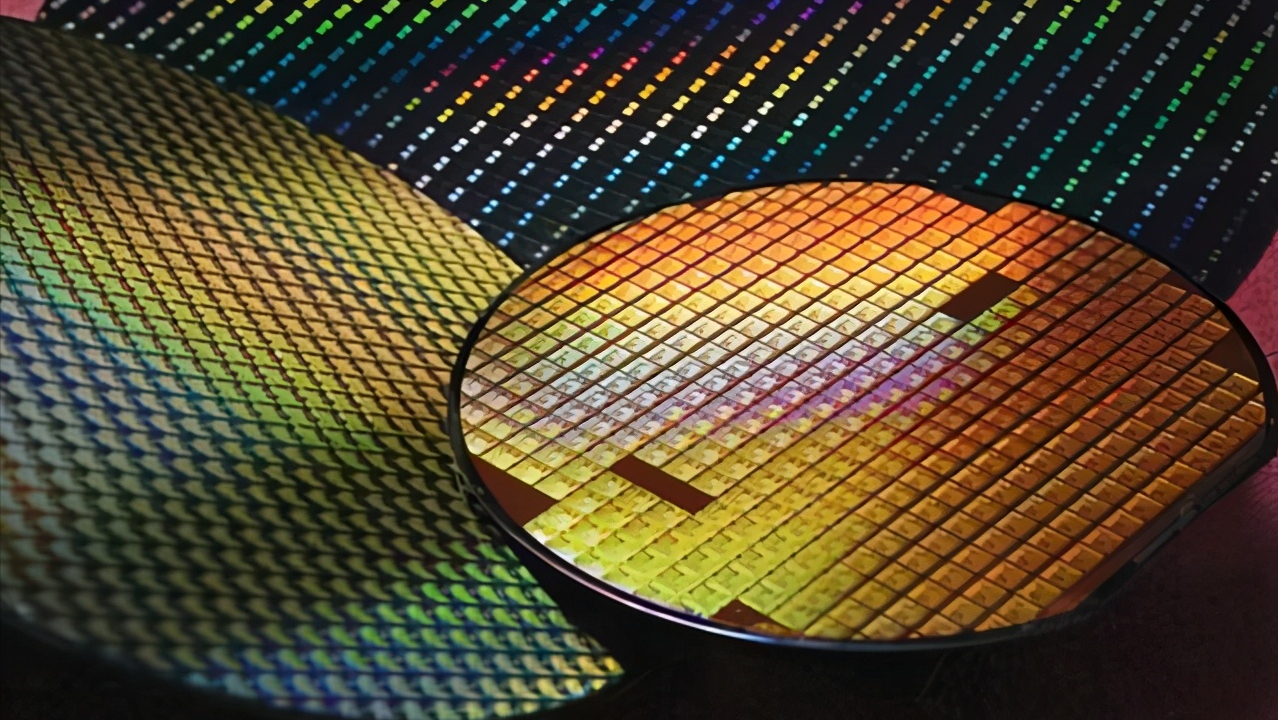

Semiconductor manufacturing is largely a chemically related process, with up to 20% of the process steps being cleaning and wafer surface preparation:

Semiconductor manufacturing is largely a chemically related process, with up to 20% of the process steps being cleaning and wafer surface preparation:

We are accustomed to referring to the chemical materials used in wafer fabrication as process chemicals, which come in different chemical forms (liquid and gaseous) and are strictly controlled in purity. The main functions of these process chemicals are as follows:

Clean the wafer surface with wet chemical solution and ultrapure water;

Doping silicon wafers with high-energy ions to obtain P-type or N-type silicon materials;

Deposition of different metal conductor layers and necessary dielectric layers between conductor layers;

Generate a thin SiO2 layer as the main gate dielectric material of MOS devices;

Use plasma enhanced etching or wet reagents to selectively remove materials and form the desired pattern on the film;

Liquid high-purity reagents are classified into three grades: UP-S, UP, and EL according to their purity, and EL is further divided into:

Electronic grade 1 (EL-Ⅰ)

has a metal impurity content of 100–1000 PPb, which is equivalent to the SEMI C1 C2 standard;

Electronic grade 2 (EL-Ⅱ)

its metal impurity content is 10-100 PPb, equivalent to SEMI C7 standard;

Electronic grade 3 (EL-Ⅲ)

has a metal impurity content of 1–10 PPb, which is equivalent to the SEMI C7 standard;

Electronic grade 4 (EL-IV)

has a metal impurity content of 0.1–1PPb, which is equivalent to the SEMI C8 standard;

Ultra-clean and high-purity reagents are internationally known as process chemicals, also known as wet chemicals, and are one of the key basic chemical materials in the production process of integrated circuits (IC) and very large-scale integrated circuits (VLSI). It is also used for cleaning and etching of silicon wafer surface. The purity and cleanliness of ultra-clean and high-purity reagents have a very important impact on the yield, electrical properties and reliability of integrated circuits. There are many varieties of electronic-grade chemicals and high technical requirements. It is based on the development of microelectronics technology. With the development of microelectronics technology, it develops synchronously or ahead of time. At the same time, it restricts the development of microelectronics technology.

Post time: Jun-23-2022